Industrial Solutions

One-Stop-Shop Solutions

We provide full-service design assistance, engineering modeling, and manufacturing solutions from early-stage prototyping to iterative development. Our one-stop-shop, vertically integrated organization allows our customers to bring better designs and forward-thinking products to the broader market.

Vertical Integration

Foresee Group has been investing in and expanding manufacturing capabilities to the downstream applications of magnetic materials for magnetic assemblies, haptic modules, motors, and other alloy parts made from MIM, CNC, and stamping. Our manufacturing service focuses on enhancing product design, performance optimization, and constomer experiences.

Precision Manufacturing

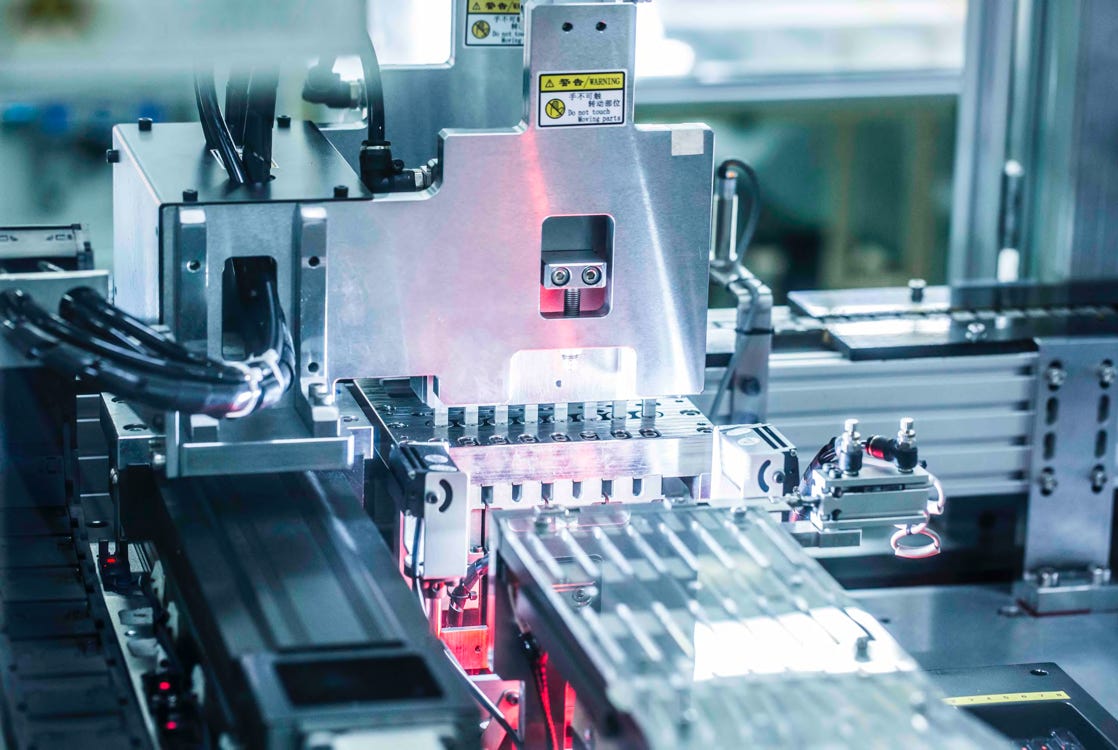

Foresee Group’s in-house precision manufacturing capabilities include magnetic material manufacturing and fabrication, injection molding processes, CNC and machining centers, tool rooms, automated plating and assembling lines, laser etching, and more. New metal alloys, haptic modules, integrated components, and other products were also developed by our R&D and engineering team to meet each application.

Automation

Automation plays a significant role in productivity, cost containment, repeatability and increased competitiveness in manufacturing. Foresee Group continually and strategically invests in equipment and staff that can creates customized automated systems which cuts cost, shorten product launch times, and meet every production schedule on time.

Dependable Quality Programs

We use cookies on this site to enhance your user experience.

Please see our Privacy Policy for details. By clicking “OK”, you are giving your consent for us to set cookies.

OK